Between sustainability promises and CO2 certificates on websites and in advertising campaigns for the furniture industry, you could get the impression that it has become an exemplary branch of industry in recent years. But how sustainable is it really? According to an EU report from 2018, the waste produced by the furniture sector within the European Union amounts to just under 11 million tonnes. This figure also includes the amount of newly manufactured furniture in Europe. 80 to 90 percent of that will be burned or disposed of at landfills, with just 10 percent getting recycled (source: European Environmental Bureau). Sustainable? Hardly! A change in thinking and a more environmentally responsible attitude are urgently needed.

By Sofia Wrede

Stricter requirements through EU regulations should finally lead to more sustainability throughout the production processes in this industry as well. Manufacturers must reduce CO2 emissions and publish information about their carbon footprint while still trying to increase their competitive edge in a challenging market environment. A real turnaround has not yet been achieved. However, we are observing that more and more companies are saving resources in intelligent ways and portraying themselves as pioneers in the field.

How do they do it – and how could the entire furniture industry take responsibility? Keyword: circular value creation. Companies and research institutes are increasingly working on directing material flows and feeding regionally available recyclables back into the cycle. In particular, recycling, the economical use of materials and components, and reducing the amount of energy used and waste generated are among the most important levers for an effective corporate sustainability strategy.

Conserving Resources: Intelligent Design Increases Usability

An inspiring example of consistent material conservation, intelligent manufacturing and high quality standards is the J*GAST kitchen. The product is the result of development work by the interior design studio Holzrausch – known for its carpentry and bespoke products – in collaboration with the designers Ana Relvão, Gerhardt Kellermann and Jan Heinzelmann. To create the kitchen, they combined an innovative system, a cosy furniture design that is compelling across all rooms, and elements of refined carpentry.

The design collective made a conscious decision to detach themselves from the classic carcass form with their concept. A standard kitchen consists of multiple box-shaped carcasses, which creates a row of double side panels once connected. Not so at J*GAST: this kitchen boasts a flat frame that is attached to the wall, as a starting point for further customizations. The patented wood structure is the support for drawers, countertops, and storage spaces, all of which can be installed using a push-fit system. Because double panels are avoided according to this principle, the system is able to conserve 45 percent of resources in comparison to other kitchens.

According to the J*GAST collective, their philosophy is based on “hedonistic sustainability.” That encompasses a sustainability that “distinguishes itself through design and intelligence, creating space for more joy in life.” Configured according to the customer’s wishes, the design deliberately dismantles previous concepts of kitchen design: whether a sideboard, cupboard, or shelf, as a versatile piece of furniture its function is not always obvious at first glance. Instead, the J*GAST kitchen is compelling thanks to its high-quality design and many handcrafted details such as delicate joints and round mouldings. J*GAST proves that the reduction of materials used in no way impairs the aesthetics of the design: made of real wood and real wood veneer, the kitchen is elegant and can be customised to fit any interior design style, thanks to a variety of aesthetic finishes.

Mono-materials: Reduction as the Key to the Circular Economy

During process optimisations around their own manufacturing operations, companies are also guided by the EU Ecodesign Directive. First adopted in 2009 as the “European framework for the for the setting of ecodesign requirements for energy-related products,” the regulations are now becoming more specific and demanding more from companies.

At the centre of the directive is the circular economy: this production and use model is predicated on existing products and materials being reused, divided up, and repaired for as long as possible in order to extend their life cycle. How is that possible? An object must be able to be completely separated into its individual components: only the purity of the materials enables the best possible reuse. Companies make their products recyclable when they can be broken down into their individual parts. To do that, they should be free of adhesives and harmful substances, especially if, for example, these could make further processing impossible for legal reasons.

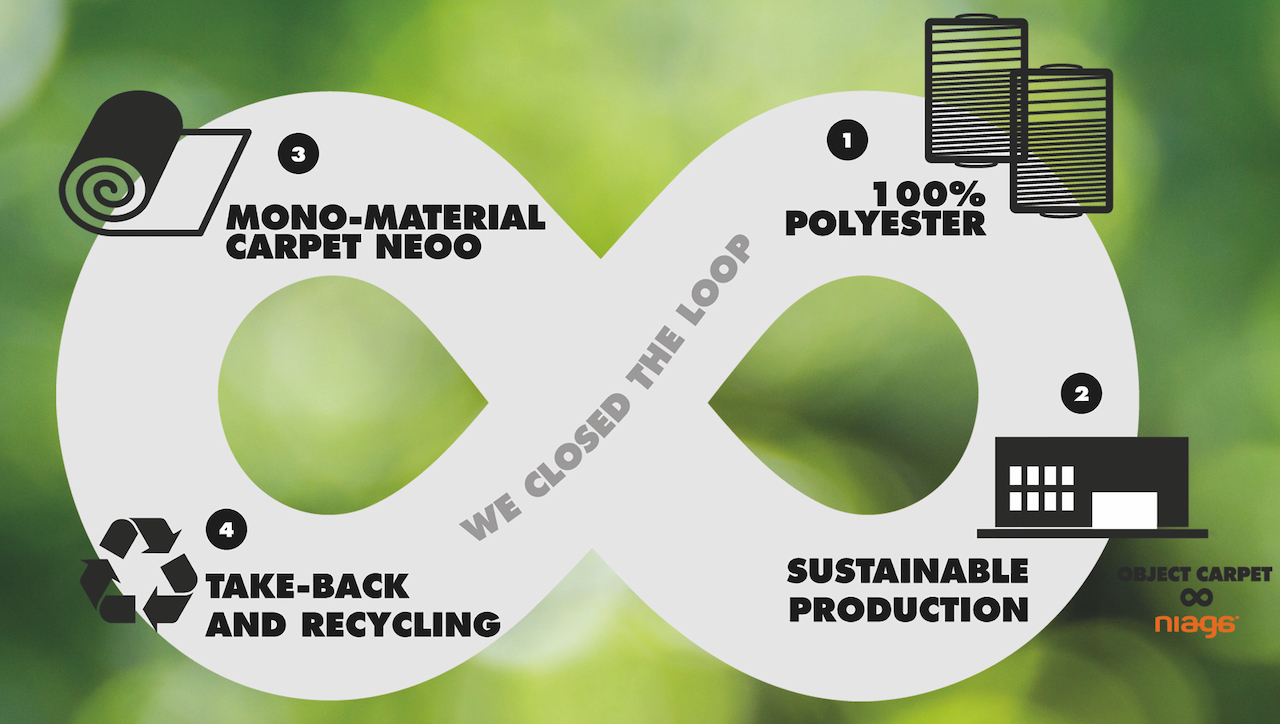

That is why manufacturers are focused on products that are mono-material and can be further processed by type: this eliminates the need for cost-intensive separation processes, and products can be fed into the recycling process without additional costly steps and material losses.

One impressive example is NEOO by OBJECT CARPET: the first one hundred percent circular carpet. Made from pure, partially recycled polyester, NEOO presents an alternative to regular carpets which are manufactured from a combination of different materials and are permanently adhered or woven together. Carpets like that can only be disposed of in the rubbish incinerator. The product developers for NEOO rely on an adhesive made of polyester: this makes the carpet mono-material and fully recyclable. Unfortunately, the possibility alone of recycling an object is hardly sufficient today. A company that is authentic in advertising the recyclability of its products defines the process of return independently. It organises, as does the manufacturer of NEOO, Object Carpet, the return of products and their further processing. Or it functions within a network that recycles furniture remains instead of burning them. NEOO carpets also come with a tag explaining the material composition and drawing attention to its circularity so that the carpet is not accidentally burnt.

The furniture industry and product designers are working on creative processes to question traditional production methods in a product-specific way and to redesign them with a view toward a sustainable processing chain. This is not only about political regulations and corporate positioning. The focus is also on a target group that uses new criteria to determine its product selection during purchasing process: both projects, J*GAST and NEOO, are an impressive demonstration of how the reduction of materials not only makes a design object more environmentally friendly, but also enhances the product identity, making it more innovative and attractive.

This is why the furniture industry will not have it easy: new challenges require investments, from research and development to new production processes and modified supply chains that need to be established.

The products presented here were honoured in 2023 at the ICONIC AWARDS: Innovative Interior. All award winners from the competition can be found at https://www.innovative-interior.com/winner

More on ndion

More articles on the topic of sustainability and interior design.

Share this page on social media: